Dewar History

Dewars are vacuum insulated containers designed to effectively hold liquefied gases (cryogens) for extended periods by reducing the heat input into the cryogen.

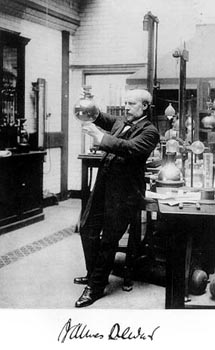

Named for their inventor, Scottish physicist Sir James Dewar, these containers gain efficiency by reducing solid, radiant, and gaseous conduction into the reservoir of the container.

They have an inner reservoir that holds the cryogen, and outer shell, and a vacuum annulus in between to minimize gaseous conduction. The vacuum annulus also commonly contains ‘superinsulation’ to minimize radiant conduction and some type of gaseous absorption getter to prolong the dewar’s vacuum. A vacuum valve is attached to the outershell as a means to evacuate air gases from the annulus and form a vacuum-tight seal.

How are they made?

Our dewars use materials that are selected based on the mechanical, thermal and economic attributees. We use aluminum extensively because it has good mechanical properties at low temperatures and it has a low emmissivity. It can be readily machined, formed, welded, painted, anodized, or plated and is both economic and durable.

Its high thermal conductivity, though useful for minimizing thermal gradients, makes it a poor choice for structural support between cold and warm surfaces. Therefore, we also make considerable use of fiberglass and stainless steel. Again, these materials excel at low temperatures, but also increase thermal isolation by virtue of their lower thermal conductivities. The use

of other materials is dictated by the requirements of the particular applications.

Dewars are constructed by joining components by means of welding, epoxy, seals, and fasteners. All components and joining methods must be verified leak-tight with mass spectrometer leak detectors. Evacuation is accomplished with a combination of pumping and baking so that the vacuum life of the dewar is maximized.

Customers work directly with Kadel’s engineers from concept to completion. We can custom design and fabricate to unique specifications, or utilize an extensive array of existing designs and products.

Our pricing is competitive and we utilize the latest CAD, manufacturing, and scheduling techniques in building our products. We design, machine, fabricate, weld, inspect, and finish all products in our facilities in Danville, Indiana. Our technicians are highly trained and our warranties are pro-rated over a five-year period. We listen to our customers and respond to their input with innovations that satisfy their particular needs.

We are eager to meet your cryogenic requirements. Please contact us for more information.