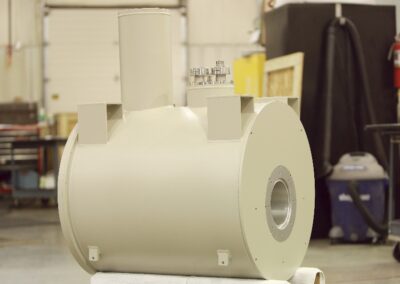

Liquid Helium Dewars

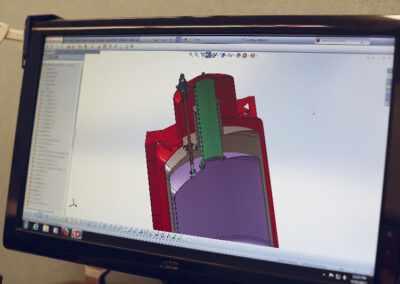

Open-mouth, or bucket-style, liquid helium dewars provide a suitable operating environment for superconducting magnets and other large experiments. Aluminum, stainless, and fiberglass dewars are available up to 40 inches diameter. Fiberglass fill necks for aluminum dewars are custom designed and fabricated in-house in any size up to 24 inches diameter. Thermal models are used to achieve the lowest practical evaporation rates.

Two types of open-mouth liquid helium dewars are commonly used in laboratory type systems: vapor-shielded and liquid nitrogen shielded. All dewars are evacuated and gettered for long vacuum life and minimal gaseous losses. Both types also use superinsulation to further reduce losses due to radiation. Vapor-shielded dewars are constructed by thermally anchoring foil shields to the neck tube at different elevations. The considerable cooling capacity of vented helium gas is utilized to remove heat from the foil radiation shields. In liquid nitrogen-shielded dewars, the helium reservoir is surrounded by either a reservoir of liquid nitrogen, or by a shield which is thermally attached to a nitrogen reservoir. This reservoir is thermally anchored to the dewar neck to form a thermal barrier to heat conducted from room temperature.

Kadel also manufactures horizontal- and vertical-bore liquid helium superconducting magnet dewars for use in NMR and similar applications. Retrofits of existing magnets into a new dewar are also available.

Typical Construction

- Aluminum, stainless or fiberglass reservoir and outer vacuum shell

- Multi-layer superinsulation

- Charcoal gettering for long vacuum life

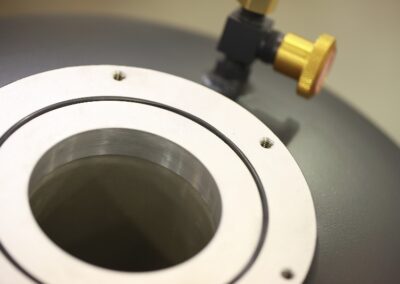

- Fiberglass fill neck with integrated diffusion barrier or stainless steel fill neck

- Bellows-sealed evacuation valve

- Lifting lugs

- Vapor or liquid nitrogen shielding

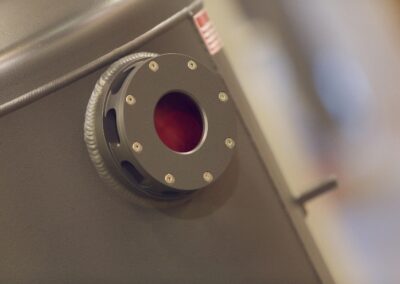

- Bolt pattern and o-ring in top plate

Options

- Liquid level probe

- Offset liquid helium fill port

- Swivel casters